The amount of WEEE generated in the world is increasing at an alarming rate and the figures are discouraging: in 2022, 62 million tons of WEEE were generated, equivalent to filling 1.55 million 40-ton capacity trucks. And it is expected to continue growing at a worrying rate, reaching 82 million tons in 2030. Only a small fraction, about 22.3%, is properly recycled, which means we are wasting billions of euros in metals such as gold, silver, copper and palladium, among others.

CirCular

What can we do to address this problem?

It is clear that we need to take urgent measures to reduce WEEE generation and responsibly manage the waste that has already been produced. Some of the possible solutions include:

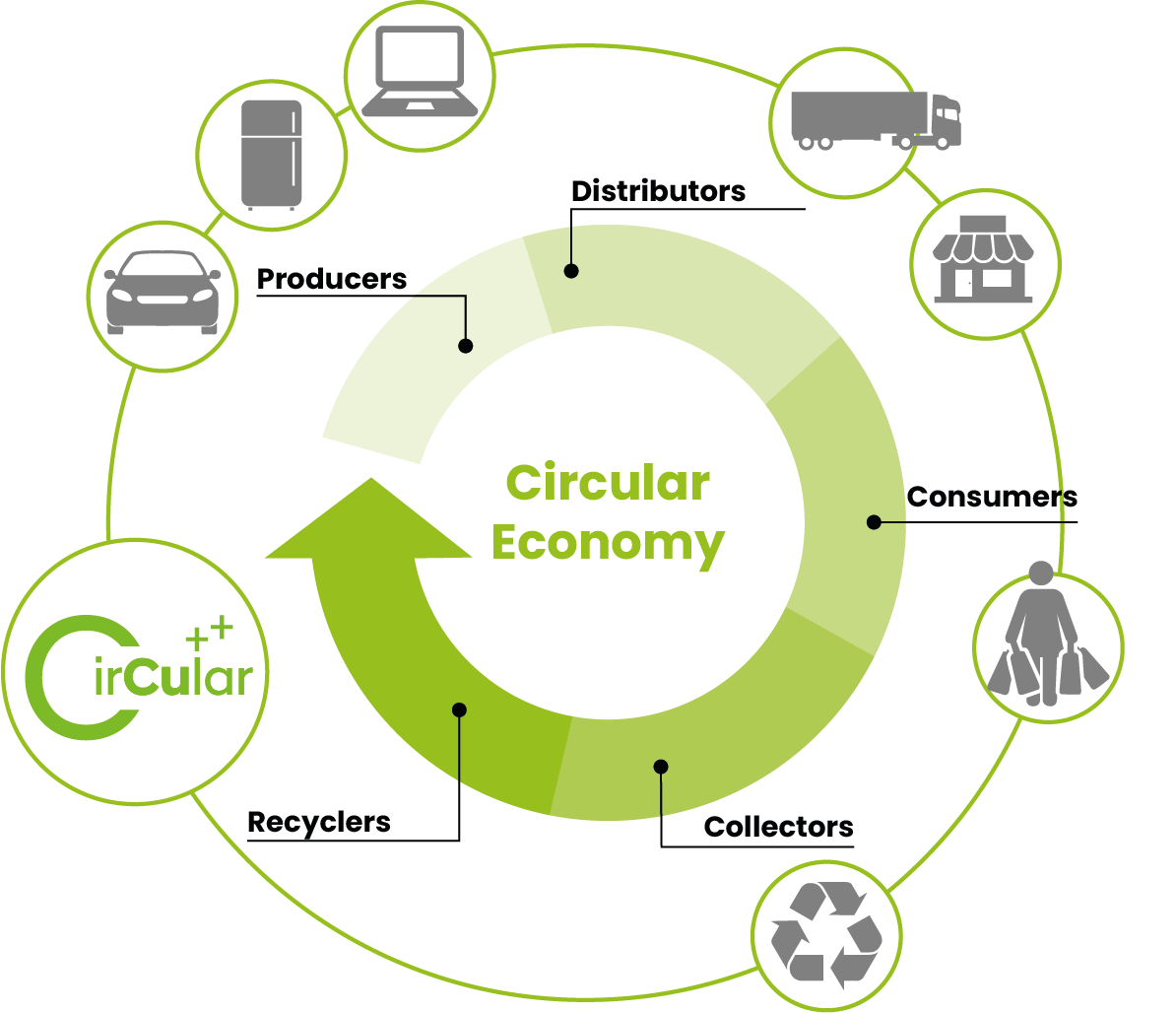

- Promoting the circular economy: Population growth and technological advancement have clearly revealed the importance of adopting a more sustainable approach in our consumption model. The circular economy emerges as a solution that seeks to minimize waste and maximize the value of resources throughout their life cycle. Within the circular economy, metal recycling and recovery play a fundamental role: copper, gold, silver, platinum and tin are widely used in technologies associated with the energy transition and sustainable mobility. By recycling these metals, we avoid the extraction of new resources and reduce the need for energy-intensive production processes.

- Promote responsible consumption: On the other hand, as consumers we must be more aware of the environmental impact of our consumption habits. It is important to buy electronic products more responsibly, considering their durability, repairability and recyclability.

What is the CirCular project?

CirCular is Atlantic Copper’s flagship circular economy project. It is a highly efficient plant with the capacity to annually process about 60,000 tons of non-ferrous metal shreds from obsolete electrical and electronic equipment (WEEE), which have already been pre-processed by authorized agents.

This project, declared of Strategic Interest by the Regional Government of Andalusia, will allow the Huelva company to recover materials such as copper, gold, silver, platinum, tin and palladium. It will become operational in 2025. In addition, the new plant, one of the most innovative in the metallurgy field in Europe and the only one of its kind in Spain, will be incorporated into the Atlantic Copper facilities in Huelva, becoming part of the metal processing chain already run by the company.

350

jobs direct, indirect and induced

€ 360 M

euros invested

60.000

tons of metal processing per year from WEEE

30

auxiliary companies at the local level

Discover our project

Treasure at home

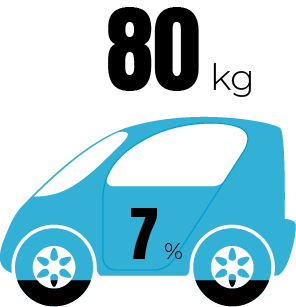

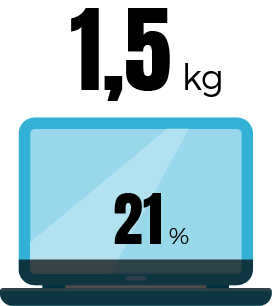

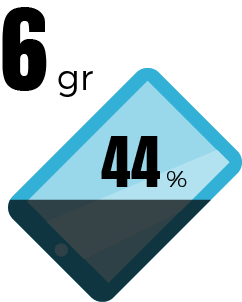

More than 5% of global waste (including organic, plastic or metal waste) corresponds to small devices such as mobile phones, batteries, cameras or laptops, known as Waste Electrical and Electronic Equipment (WEEE). All of them contain different amounts of copper and other metals such as gold, silver, palladium, platinum, tin and nickel, which we will recover in our high-tech plant located in the Atlantic Copper facility starting in 2025, after have been treated in authorized centers, to supply these products and give them a new life.

"Committed to the circular economy for decades"

For several decades, we at Atlantic Copper have been committed to circular energy, heat and water projects, among others, which have been supported by European bodies and other institutions.

Some of our projects are:

- New technologies for recovering heat from the process to convert it into electrical energy that we consume ourselves.

- RedScope Project: co-financed by the EIT RawMaterials, and which involves the start-up of a new industrial water recovery plant (Zero Liquid Discharge). Starting-up the plant will allow us to reuse about 500,000 m3 of water per year, equivalent to the annual consumption of 10,000 people. In this way, we contribute to reducing our environmental impact and the company’s water footprint by 25%.

- Renew Project: co-financed by the EIT RawMaterials, and which aims to validate technologies capable of separating plastics from metals present in Printed Circuit Boards (PCBs) commonly found in WEEE.