The history of copper has always been linked to humanity’s progress. Societies have undergone major changes since beginning to use copper 10,000 years ago for its unique properties: malleability, resistance and durability. Today, copper is an excellent thermal and electric conductor, 100% recyclable and antimicrobial, and is essential for the challenges of decarbonization, energy transition and sustainable mobility.

Copper

Uses of copper

Copper has a wide range of industrial and domestic applications, being used mainly in the following sectors:

Construction

Piping (plumbing, bathroom fittings, heating, air conditioning), architecture, fire detection, house and building wiring, decoration.

Electricity and Motors

Low and high voltage wiring, motors, information technologies.

Consumer products

Home appliances, coins, cell phones and computers.

Transportation

Conventional, electric and hybrid cars, high-speed trains, ships and aircraft.

Industrial Machinery

Capacitors, reactances, motors, heat exchangers and valves.

"We are the foremost refined copper producer in Spain and the third largest smelter and refinery in Europe"

End product

Cathodes

The cathode copper we produce in our metallurgical complex in Huelva achieves 99.99% purity. Most of our refined copper sales go to the manufacture of high-quality copper wire rod, which will then be transformed into wires and cables, mainly for electrical use. Our product is marketed in packs containing approximately 60 pieces, with a total weight of around 3,000 kg.

Certification: Registered on the top four exchanges in the world (LME, COMEX, SHFE and INE).

DEFINITION

Copper plate produced by electrolytic deposit on an initial cathode of stainless steel.

TYPES OF CATHODE

High quality cathode.

Rejectable cathode (R).

CHEMICAL COMPOSITION

Specifications of the “Cu-CATH-1 (CR001A)” and “EN 1978:1998” Standard.

DESIGNATION

According to the E-Re 03, specifications of the “Cu-CATH-1 (CR001A)” and “EN 1978:1998” standard. The designations are:

| Designation | European Standard No. | Material designation | |

| Cathode | EN-1978 | – | Cu-CATH-1 |

| Cathode | EN-1978 | – | CR001A |

PHYSICAL CHARACTERISTICS

- Compact structure.

- Non-brittle.

- Free from the presence of foreign material.

- Well washed.

- They will be classified according to the E-In 11 instruction.

WEIGHT

Variable, depending on the batch and processing conditions, and may reach up to 60 kg.

DIMENSIONS

They will measure 985 x 930 mm., with a deviation of ± 15 mm, and may be smaller provided that they meet the physical and chemical specifications.

MAXIMUM IMPURITIES IN HIGH QUALITY CATHODES

| Group | Element | Specifications (ppm) | |

| Element | Group total | ||

| 1 | Selenium | 2 | 3 |

| Tellurium | 2 | ||

| Bismuth | 2 | ||

| 2 | Chromium | – | 15 |

| Manganese | – | ||

| Antimony | 4 | ||

| Cadmium | – | ||

| Arsenic | 5 | ||

| Phosphorus | – | ||

| 3 | Lead | 5 | 5 |

| 4 | Silicon | – | 20 |

| Tin | – | ||

| Nickel | – | ||

| Cobalt | – | ||

| Zinc | – | ||

| Iron | – | ||

| 5 | Sulfur | – | 15 |

| 6 | Silver | – | 25 |

Maximum permitted: 65

Source: EN- 1978:1998 STANDARD

Anodes

Anodes are an intermediate product in the copper processing chain. Only the surplus production not used for cathode making in the refinery is marketed.

CHEMICAL COMPOSITION

Anodes must meet the following contents per molded load:

Cu > 99 %

As < 2500 ppm

Sb < 550 “

Se < 700 “

PHYSICAL CHARACTERISTICS

- Lug thickness: 33 – 47 mm

- Distance between lugs: 1237 – 1253 mm

- Body thickness: 45 – 58 mm

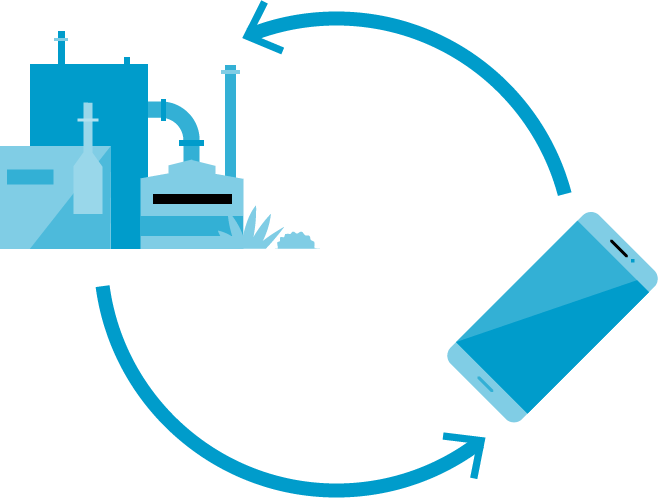

Recycled copper

Copper is a metal that can be recycled countless times, without this altering its properties.

- Currently, more than 30% of the world’s copper consumption comes from recycled sources, while in Europe this figure exceeds 50% (data from Wood Mackenzie, 2023).

- Recycled copper has many benefits:

- Copper recycling requires up to 85% less energy than primary production, which, on a global level, represents a savings of 40 million tons of CO2 per year.

- Reuse of copper in the manufacture of new products makes it possible to reduce the environmental impact caused by the extraction of finite raw materials, and greenhouse gas emissions.

Atlantic Copper has the capacity to process up to 35,000 tons of used copper a year. It comes to us in diverse forms, such as copper pipes and wires, granules, in shavings or coins. Copper granules are also blended with precious metals.

In data

1,100,000 t

Concentrate melting capacity

35,000 t

Recycled copper melted down per year

285,000 t

Cathode capacity