Sulfuric acid is the most-produced and most-consumed chemical worldwide and has become an essential raw material for many industries. This is why the level of sulfuric acid consumption and production is used as one of the indicators of a country’s degree of industrial development. On a yearly basis, Atlantic Copper produces more than one million metric tons of this substance, which is essential for the fertilizer industry and pharmaceutical sector.

Sulfuric Acid

Uses of sulfuric acid

It is not known exactly when sulfuric acid was discovered. The first historical reference is found in Persia, around the 9th century AD. The alchemists of medieval Europe used sulfuric acid, which they called oil of vitriol, one of the most appreciated substances in their formulas. Chronicles of the time say that it was even used in the fruitless search for the philosopher’s stone.

What we can say with some confidence is that sulfuric acid was first obtained industrially in England in the 18th century, using the so-called “lead chamber” method.

Today, the most widely used industrial method for sulfuric acid production is the contact process. This process is based on the use of a catalyst to convert sulfur dioxide (SO2) into sulfur trioxide (SO3), from which sulfuric acid is obtained by hydration (SO3+ H2O to H2SO4).

Our production of sulfuric acid originates with the sulfur contained in the copper concentrates processed in the metallurgical complex. This sulfur is released as a gas during the smelting and conversion processes.

Gases with a sulfur dioxide content of 25-30% are produced in the smelting process in the flash furnace, while gases produced during the conversion process have a sulfur dioxide content of between 7% and 10%. Both the smelting and conversion gases, after their dusting, washing and cooling, are sent to the three sulfuric acid plants in our Huelva metallurgical complex.

With production exceeding one million metric tons per year, we are the largest producer of sulfuric acid in Spain and the third largest in Europe.

| Specification | Typical analysis | |

| H2SO4 (%) | > 98 | 98.5 |

| As (ppm) | < 1 | 0.4 |

| Fe (ppm) | < 15 | 6 |

| Cu (ppm) | < 0.6 | 0.3 |

| Mn (ppm) | < 0.4 | 0.1 |

| Cd (ppm) | < 0.1 | < 0.1 |

| Zn (ppm) | < 0.3 | 0.2 |

| SO2 (ppm) | < 20 | 11 |

| Hg (ppm) | < 1 | 0.5 |

| Turbidity (NTU) | < 20 | 2 |

| Colour (Hazen) | < 80 | 50 |

| Cr (ppm) | <1 | 0.6 |

| Pb (ppm) | < 0.4 | 0.2 |

| Ni (ppm) | < 1.5 | 0.8 |

| Fixed Residue

(ROI, 500ºC) (ppm) |

< 250 | 70 |

| Reducing substances

(KMnO4, 0’0125 N) (ml) |

< 5 ml | < 5 ml |

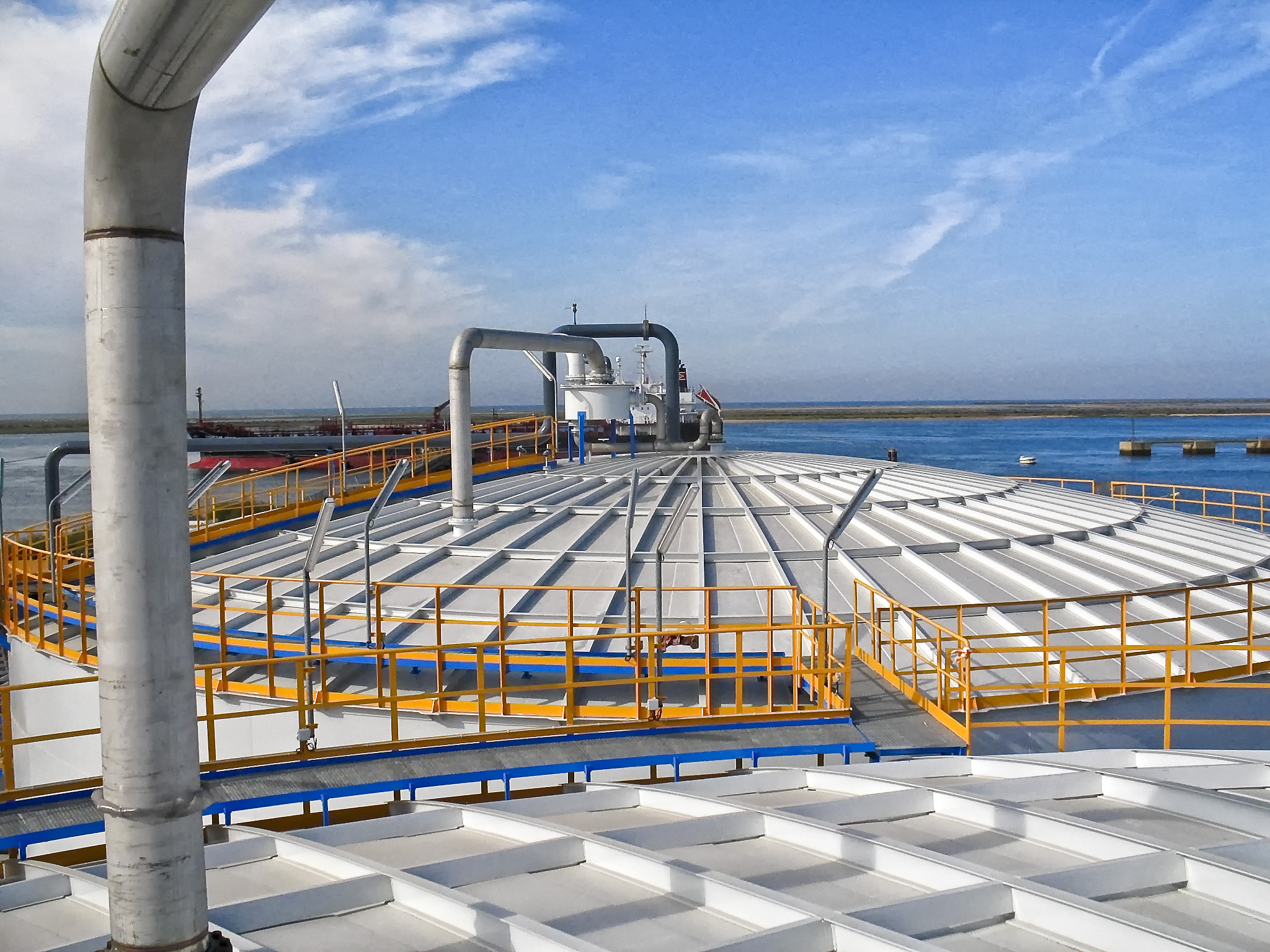

Our logistics infrastructure is very flexible and is perfectly adapted for the storage, shipping and transport of sulfuric acid, whether by land, sea or even multimodal transport. The Huelva and Palos de la Frontera terminals have three jetties, which can accommodate ships of between 6,000 and 25,000 deadweight tons. Moreover, we have a train loader and two trucks with simultaneous loading capacity of up to four tanks. We also have sizeable storage capacity in both the metallurgical complex and the Palos de la Frontera terminal.

This logistics infrastructure allows us to market our sulfuric acid in Spain, Europe, Africa, the Middle East and the Americas.